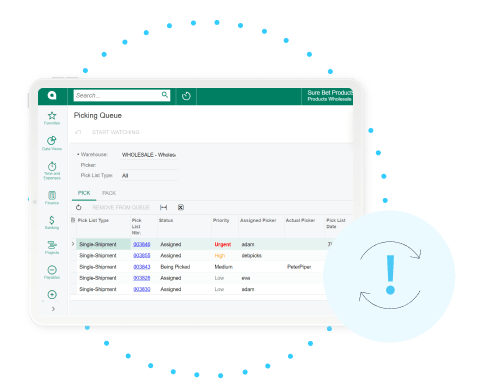

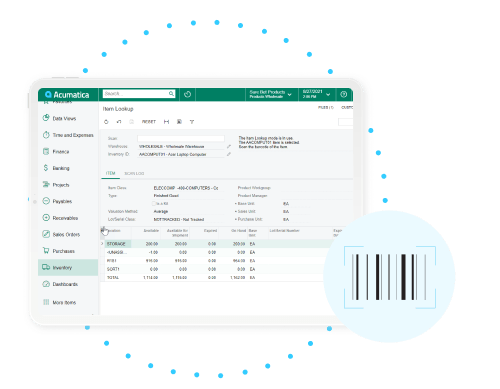

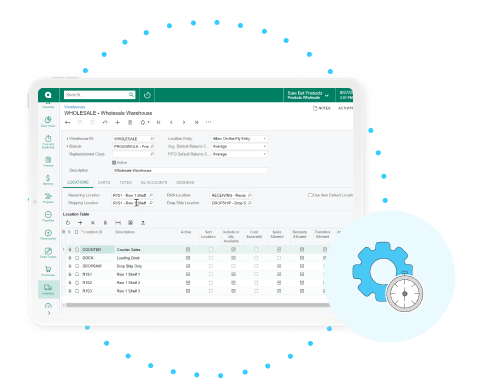

A warehouse management system (WMS) is a software solution that supports the essential processes—both simple and complex—of managing a warehouse. These warehousing processes include receiving, storing, and monitoring inventory; retrieving inventory through the pick-and-pack process; shipping orders; reporting on shipment accuracy (e.g., correct shipments, over-shipments, under-shipment, and shipping incorrect items); and communicating with suppliers and transportation vendors who are responsible for providing materials and shipping orders.

With a WMS, these core processes are automated and fully managed using role-based dashboards. When purchased as part of a cloud-based Enterprise Resource Planning (ERP) solution, a WMS takes warehouse management to the next level by storing and synchronizing data from the WMS and other ERP modules—such as accounting, customer resource management, and human resources—in a centralized database.

Accessing this real-time, accurate, and company-wide data in a single cloud-based system fuels the ability to complete forecasting, analysis, compliance, and planning tasks, to optimize warehouse performance, and to drive improvements.

Canada (English)

Canada (English)

Columbia

Columbia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malasya

Malasya

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri-Lanka

Sri-Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States